In scenarios such as automotive maintenance and industrial equipment upkeep, dry ice cleaning technology is widely utilized for its efficiency and environmental benefits, particularly in removing engine carbon deposits. However, many wonder: where do those stubborn carbon deposits adhering to component surfaces go after dry ice cleaning?

The core principle of dry ice cleaning is the dual effect of “physical impact + low-temperature embrittlement.” Dry ice is solid carbon dioxide, with a temperature as low as -78.5°C. During cleaning, dry ice pellets are sprayed at high speed onto the carbon buildup surface using specialized equipment. The instant low temperature causes the carbon to become brittle and lose its original adhesion. Simultaneously, the high-speed moving dry ice pellets act like countless tiny “bullets,” delivering intense physical impact to the embrittled carbon buildup and removing it from the surface of the parts.

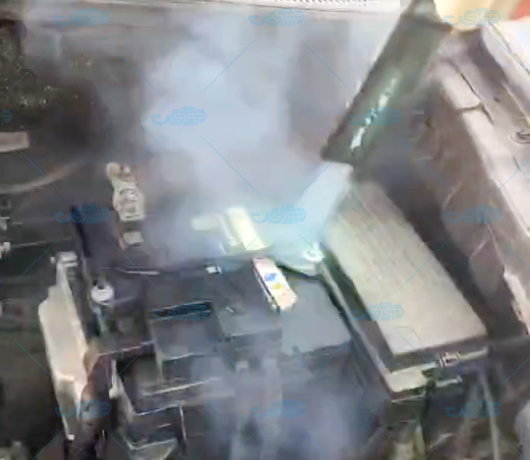

The detached carbon deposits turn into fine powdered particles, mixing into the airflow generated during the cleaning process. As dry ice rapidly sublimates upon contact with the object’s surface, transitioning directly from solid to gaseous carbon dioxide, its volume expands hundreds of times instantly. This expansion force drives the surrounding airflow, creating a powerful “blow effect.” Under the force of this airflow, the fine carbon deposits are promptly carried away, removing them from the cleaning area.

In professional cleaning operations, vacuum equipment is typically used in conjunction. When carbon deposits are stirred up by airflow, the vacuum device simultaneously activates, drawing most of the carbon powder into a collection bag to prevent it from dispersing into the air and causing pollution. The small amount of fine carbon particles that remain uncollected will naturally settle or dissipate in a ventilated environment. However, due to their extremely tiny size and absence of harmful substances, they pose no impact on the environment or human health.

To put it simply, the carbon deposits after dry ice cleaning are first shattered into powder, then “packaged and removed” through air blowing and professional dust extraction, ultimately achieving a complete separation of carbon deposits and parts. This not only fulfills the cleaning task but also avoids secondary pollution, which is the key to the environmental efficiency of dry ice cleaning technology.

Horse Leads New Journey, First Order Shines Start | Niutaiupu Dry Ice Equipment Foreign Trade Greets the First Order of the New Year

As the spring breeze blows and the Year of the