Environmental worry free: After sublimation, dry ice turns into carbon dioxide and returns to the atmosphere. The entire cleaning process does not produce pollutants such as wastewater and waste residue, which meets the current strict environmental requirements and allows enterprises to clean equipment without worrying about environmental penalties.

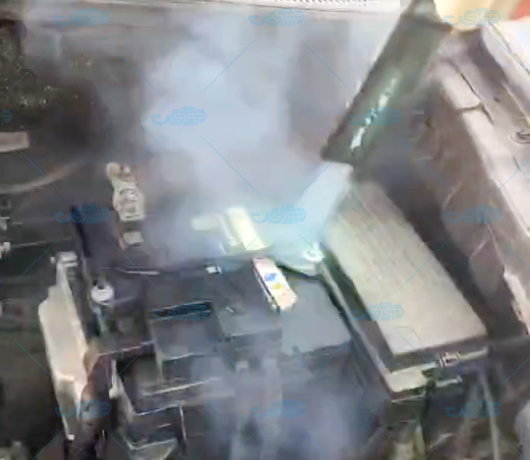

Efficient and time-saving: Compared to traditional cleaning methods that often take several days, dry ice cleaning can quickly complete tasks. Its flexible and convenient operation mode can accurately adjust cleaning parameters according to the actual situation of the equipment, greatly reducing equipment downtime and ensuring production continuity.

Precise cleaning: Dry ice particles can accurately act on dirty areas, achieving just the right level of cleaning for sensitive areas and delicate components of equipment, avoiding potential damage caused by “excessive cleaning” to the equipment.

Whether it is the demanding requirement for stable power transmission in transformers or the pursuit of efficient heat exchange in heat exchangers, dry ice cleaning can perfectly cope with its excellent performance. Choosing dry ice cleaning injects strong power into the long-term operation of equipment and the sustainable development of enterprises, enabling industrial production to steadily move forward on a clean and efficient track. Trusting dry ice cleaning opens a new chapter in industrial equipment maintenance.http://www.ntpco2.com

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,