Industrial production, injection molds, die-casting molds, rubber molds, etc. are easy to accumulate pollutants such as oil stains, plastic residues, release agents and carbon deposits after long-term use. The traditional cleaning method has multiple problems:

Chemical cleaning: the solvent may affect the coating on the mold surface, and the residual agent needs special treatment;

High pressure water cleaning: water may penetrate into the mold gap, and the subsequent drying process takes a long time;

Sand blasting cleaning: the abrasive may cause mechanical wear on the mold surface, and the dust residue is easy to block the precision structure.

Core demand: how to effectively remove stubborn stains in complex structures while protecting mold accuracy has become the focus of the industry.

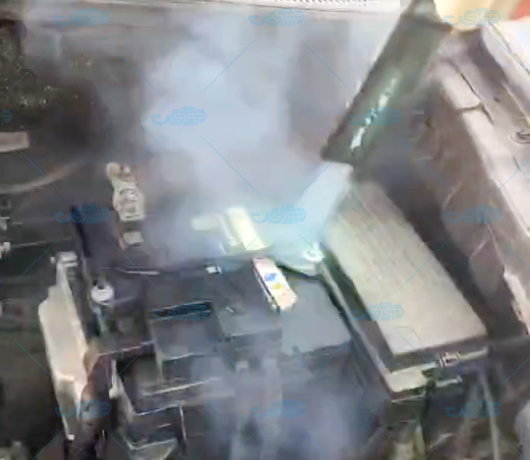

Dry ice cleaning: a physical cleaning scheme suitable for industrial molds

Wantong dry ice cleaning technology realizes cleaning through physical mechanism. Its main advantages are as follows:

Non abrasive properties to reduce surface damage

The hardness of dry ice is low. During the cleaning process, the pollutants are stripped by kinetic energy impact and temperature difference effect to reduce the mechanical wear on the mold surface (such as mirror mold and coating mold). After testing, it can effectively reduce the risk of surface scratches that may be caused by traditional cleaning methods.

Go deep into complex structures to improve cleaning coverage

The dry ice particles penetrate into the mold buckle, hot runner, exhaust slot and other parts with the air flow. The low temperature environment changes the physical properties of some pollutants, which is easy to peel off. In practical application, the utility model can clean the tiny gaps that are difficult to reach in the traditional way, and improve the overall cleaning effect.

Water free operation, reducing downtime

No water is needed in the cleaning process to avoid the subsequent drying process. Compared with the traditional water cleaning, it can reduce the time-consuming of relevant processes. Taking a certain type of injection mold as an example, the single cleaning time can be shortened by about 50% compared with the traditional method, helping enterprises reduce the impact of equipment downtime.

Environmental protection, safety and compliance with multi domain standards

There is no solid or liquid residue after dry ice (carbon dioxide) cleaning. In scenarios with high cleaning requirements, such as food packaging molds and medical consumables molds, it can reduce the risk of chemical residue and meet the health standards of relevant industries.

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,