After removing the scaling and dust from the air preheater, the improvement in boiler efficiency is reflected in multiple dimensions, and the effect can be quantified:

1. Restore heat transfer efficiency and reduce heat loss

After the dust and scaling are removed, the heating surface of the air preheater (such as fins and tube rows) is completely exposed, and the heat exchange area between the flue gas and air returns to the design value. Data shows that after cleaning, the exhaust temperature can be reduced by 30-50 ℃. Calculated based on the proportion of boiler exhaust heat loss to total heat loss of 60% -70%, the boiler thermal efficiency can be improved by 2% -5% (depending on the degree of pollution accumulation).

2. Reduce system resistance and energy consumption

After solving the problem of reducing the cross-sectional area of smoke circulation caused by accumulated pollution, the wind pressure requirements of induced draft fans and supply fans are reduced, and the power consumption of motors can be reduced by 10% to 20%. Taking a 1000t/h boiler as an example, a single fan with a power of about 500kW can save hundreds of thousands of yuan in electricity bills annually after cleaning.

3. Optimize combustion conditions and reduce fuel waste

After the air preheater returns to normal, the temperature of the air entering the furnace increases (usually reaching 200~300 ℃), the fuel combustion is more complete, the excess air coefficient decreases (from 1.3~1.5 to 1.1~1.2), and fuel consumption can be reduced by 3%~8%. At the same time, sufficient combustion can also reduce the content of unburned substances such as carbon monoxide and carbon black in the flue gas, reducing environmental pollution.

4. Extend equipment lifespan and reduce downtime losses

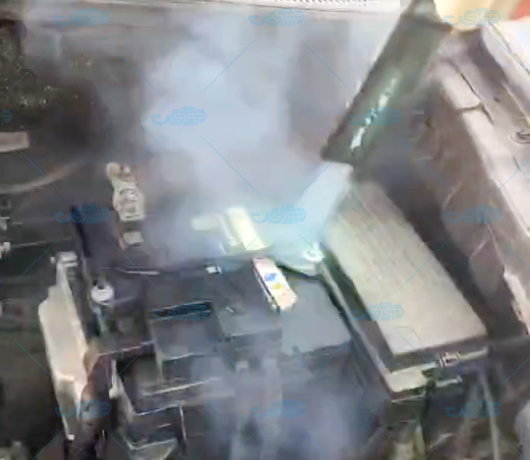

Dry ice cleaning is a non-contact physical cleaning that does not damage the metal on the heating surface (no wear, no corrosion), and avoids the problem of acid and alkali residue caused by chemical cleaning. After cleaning, the risk of corrosion and tube bursting of the air preheater is reduced, and the maintenance cycle can be extended from 3-6 months to 1-2 years, reducing downtime maintenance time by 50-100 hours per year and indirectly improving the effective operation time of the boiler.http://www.gbqxsb.com

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,