With the development of the industry, dry ice blasting machines are gradually becoming a trend in the cleaning industry. Dry ice blasting machines, also known as dry ice blasting technology, are widely used in the cleaning industry. In most factories, dry ice blasting machines are widely used to clean sand core molds, vulcanization molds, rubber molds, tire molds, and fixed mechanical equipment to solve factory cleaning problems.

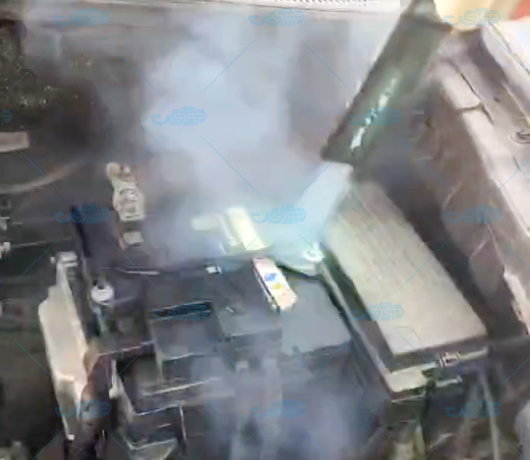

The primary cleaning medium of dry ice blasting machines is dry ice. Due to its volatility, the physical low temperature and high-speed freezing of dry ice blasting brittles dirt, and the dry ice pellets and carbon dioxide immediately sublimate. Upon contact with the object, dry ice forms cracks and rapidly expands. As the dirt’s adhesion decreases, the effects of dry ice quickly disappear. The entire cleaning process utilizes the physical low temperature and gentle impact of dry ice to affect the dirt structure, achieving a cleaning effect without the use of chemical additives. This is environmentally friendly and does not affect the product’s smoothness.

Dry ice blasting typically consists of two parts: the blasting machine and the dry ice pellet production. Compressed air from an air compressor accelerates dry ice pellets at -78.5°C to high speed and blasts them onto the surface.

For industrial cleaning services, choosing a dry ice cleaner can save labor costs, improve cleaning efficiency, reduce production costs, and address the wear and tear associated with traditional cleaning products. Dry ice cleaning machines can clean molds in-line without stopping or waiting for the mold to cool, making it easy to remove mold layers and residue. This cleaning method is less likely to wear and damage the mold, but it can also clean some microporous molds.http://www.ntpco2.com