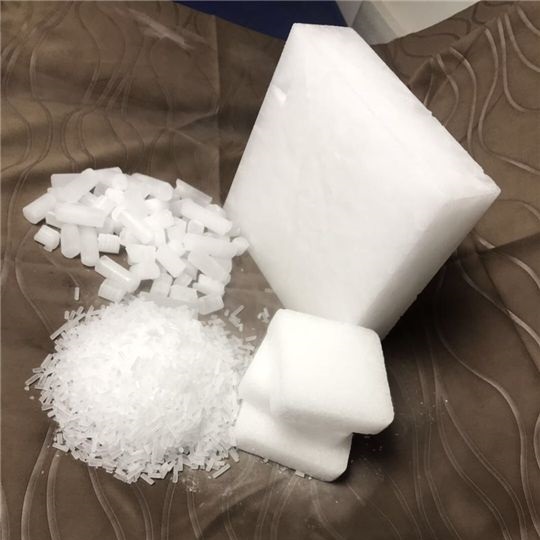

In the field of food preservation, dry ice is gradually emerging and has many unparalleled advantages compared to traditional ice cubes.

From the perspective of temperature control, dry ice is solid carbon dioxide that directly changes from solid to gaseous state during sublimation. This process can absorb a large amount of heat, causing the surrounding environment temperature to rapidly drop to around minus 78.5 ℃. Ice cubes are made by freezing water and can only maintain a temperature of 0 ℃ when melted. In contrast, dry ice can create a lower and more stable low-temperature environment. For foods such as ice cream, fresh meat, and deep-sea fish that require high temperature, low temperature dry ice can greatly delay the growth of microorganisms and chemical reaction rates. For example, high-end steak, under the low temperature created by dry ice, freezes the water inside its cells slowly, and the ice crystals form small particles, effectively avoiding the deterioration of meat quality caused by cell rupture, and can lock in juice and fresh taste for a long time; On the other hand, when it comes to ice preservation, the temperature range close to 0 ℃ is prone to a decrease in microbial activity, but it is still significant, and the shelf life of food is relatively much shorter.

When it comes to preservation time, the sublimation process of dry ice is slow. Under good sealed packaging conditions, an appropriate amount of dry ice can provide several days or even weeks of low temperature protection for food. Taking the cross-border transportation of cherries as an example, they are immediately preserved and packaged with dry ice after being picked from the production area. After a long journey and customs turnover, when they reach the hands of consumers, the fruit is still full, brightly colored, and has an extremely low loss rate; Ice cubes are limited by their melting speed and have a relatively short shelf life. They usually need to be replaced within a few hours, otherwise melting into water will not only wet food, damage packaging, breed bacteria, but also accelerate food spoilage.

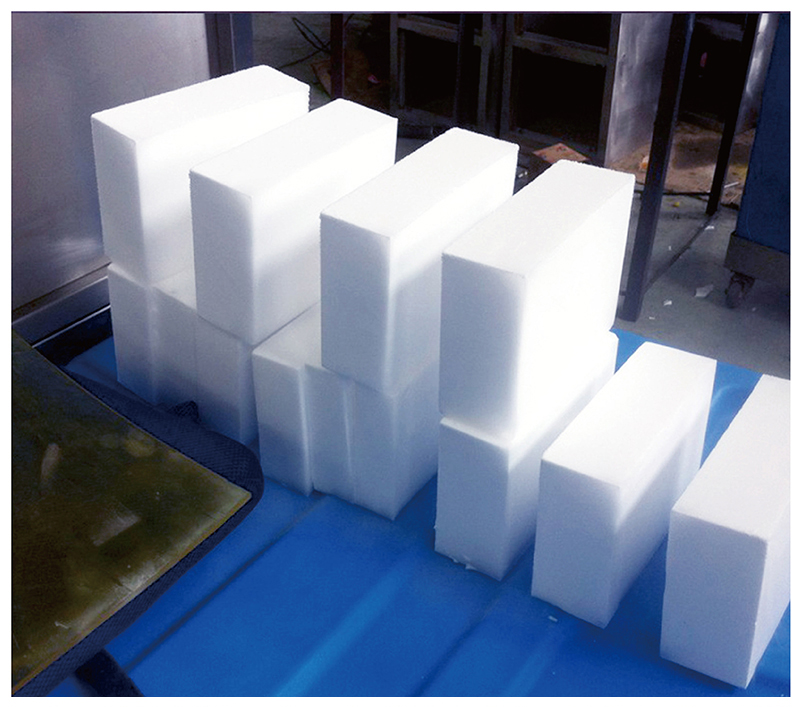

In terms of convenience and safety, dry ice also has outstanding advantages. Dry ice is not as bulky and space intensive as ice cubes. With the same cooling capacity, dry ice is compact and lightweight, which can save a lot of transportation capacity, reduce logistics costs, and facilitate large-scale and long-distance distribution of food. Moreover, after sublimation, dry ice becomes carbon dioxide gas and dissipates, leaving no residual moisture to contaminate food or packaging, avoiding the risk of moisture and mold in food. For delicate pastries, high-end tea and other foods that are most sensitive to moisture, dry ice is the most ideal preservation companion; The water generated by the melting of ice cubes requires additional treatment, and a slight carelessness can pose a food safety hazard. It is also inconvenient to carry, and even a slight shake of the packaging can cause water stains to flow freely.

From a hygiene perspective, dry ice preparation technology is mature, with high purity. Under standard production processes, it contains almost no impurities or microorganisms, and does not introduce additional sources of contamination when in contact with food; The water source for making ice cubes is complex. If the water source itself is contaminated or the ice making equipment is not cleaned properly, the risk of harmful substances such as bacteria, viruses, and heavy metals being carried by ice cubes increases significantly. Using ice cubes for food preservation is undoubtedly “inviting wolves into the house” and poses numerous hidden dangers to food safety.

In summary, dry ice, with its excellent temperature control ability, long shelf life, convenience and safety, and high hygiene, has won the competition for food preservation over ice cubes, providing fresh supply for the modern food industry and has become the best choice for high-quality food preservation.