Dry ice cleaning machines have been widely used in many industries due to their high efficiency, environmental friendliness, and non-destructive advantages.

In the field of industrial manufacturing, small dry ice cleaning machines have shown their skills. Taking mold cleaning as an example, whether it is tire molds, rubber molds, injection molds, etc., after long-term use, residual resin, ineffective delamination layer, carbonization film agent and other dirt will remain on the surface. Traditional cleaning methods may require disassembling the mold, which is not only time-consuming and labor-intensive, but may also cause damage to the mold. The small dry ice cleaning machine can be cleaned online without the need for cooling or disassembling the mold. Dry ice particles are sprayed onto the surface of the mold under high-pressure air, utilizing a low temperature of -78 degrees Celsius to make the dirt brittle, instantly vaporizing and expanding 800 times to generate strong peeling force, quickly removing the dirt and making the mold shiny as new, reducing downtime by about 80% -95%. In the electronics industry, small dry ice cleaning machines are also very effective in cleaning grease, dirt, and post weld solder paste, contaminated coatings, etc. inside robots and automation equipment, as well as on integrated circuit boards. Electronic devices are precise and require extremely high cleanliness. Dry ice cleaning does not leave liquid residue like traditional cleaning methods, avoiding problems such as short circuits caused by liquid residue and ensuring the safe operation of electronic devices.

The food and pharmaceutical industry has almost strict requirements for hygiene standards, and small dry ice cleaning machines also perform well in this industry. In the process of food processing, baking residues, gelatinous substances, oil stains, and fresh product mixtures before baking may adhere to the surfaces of ovens, mixing and stirring equipment, conveyor belts, etc. Dry ice cleaning can successfully remove these dirt, and because it does not require the use of harmful chemicals, it avoids production equipment from coming into contact with harmful chemicals and generating secondary waste. It can also inhibit or remove bacteria such as Salmonella and Listeria, achieving more thorough disinfection and cleanliness. In the pharmaceutical industry, small dry ice cleaning machines can be used to clean equipment such as reaction vessels and condensers, ensuring that the equipment is clean and pollution-free, and meets strict hygiene standards for drug production.

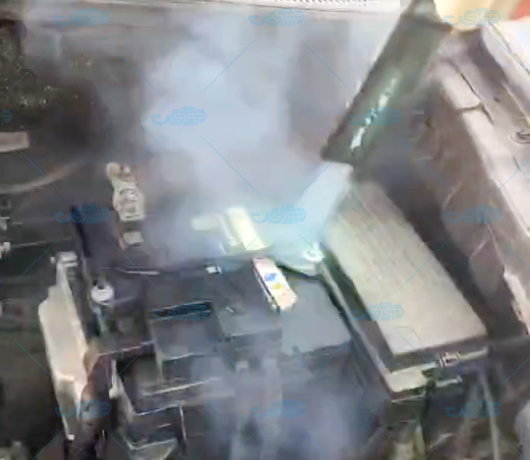

In the power industry, small dry ice cleaning machines can clean power boilers, condensers, and various heat exchangers. They can also directly clean indoor and outdoor transformers, insulators, distribution cabinets, wires, and cables with live loads (below 37KV). Traditional cleaning methods may require power outages, which can affect the stability of power supply. Dry ice cleaning can effectively remove dirt from the surface of equipment without power outages, effectively stripping away the pollutants being cleaned, reducing power loss, lowering the maintenance costs of external and basic equipment, and improving the reliability of the power system. http://www.gbqxsb.com

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,