Dry ice cleaning is a common cleaning method. Nowadays, dry ice cleaning technology has been widely used in various fields, with the characteristics of safety, no pollution, fast speed, and low cost. It is also somewhat similar to traditional cleaning methods. Let’s take a look at the advantages and applications of dry ice cleaning together. Advantages of dry ice cleaninghttp://www.ntpco2.com

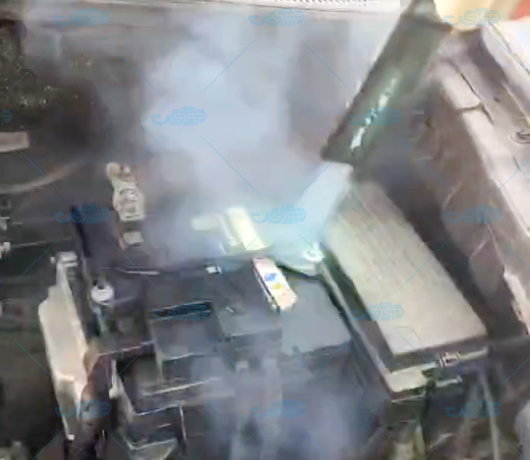

1. The significant feature of dry ice cleaning is that it can be cleaned online, especially the hot cleaning effect is more significant. Online cleaning can greatly shorten equipment downtime and reduce the impact of the cleaning process on production. For enterprises engaged in continuous production, it can bring significant economic benefits, as well as save water, detergent, and reduce labor intensity for workers.

2. Due to the fact that only the cleaned dirt remains after dry ice cleaning, the dry ice particles have already vaporized into carbon dioxide gas without any other chemical residues, which does not cause pollution to the environment. Traditional detergent cleaning can cause secondary pollution to water bodies and the environment, and also increase the burden of urban water treatment.

3. Dry ice cleaning has unique thermal and mechanical effects, making it superior in cleaning, especially for fine textures and dense pores on precision molds. It does not damage molds and precision parts, does not change tolerances, and does not affect the surface smoothness of objects. Application of dry ice cleaning

1. Automotive industry

Thoroughly clean the weld and polyurethane foam mold; Cleaning of automotive interior and panel molds, seat molds, tire and gasket molds; The small and compact area of the glue applicator can be cleaned without disassembling the equipment; Clean excessively sprayed paint to ensure smooth demolding of parts.

2. Foundry industry

Clean the graphite lubricant on the conveyor belt and die-casting machine; Clean up excess grease, dust, ink, or carbon on production equipment and hydraulic power units.

3. Food and Beverage

The cleaning of the food industry is aimed at maintaining food hygiene, mainly cleaning food containers and processing equipment. Dry ice cleaning is a physical process that is dry and environmentally friendly.

4. Rubber industry

The main problem with rubber molds is mold and dirt. Dry ice cleaning has a significant effect on the accumulation of cleaning curing materials and release agents.