In the field of automobile manufacturing, the cleaning and maintenance of molds are crucial, and dry ice cleaning technology is bringing a new revolution to this process.

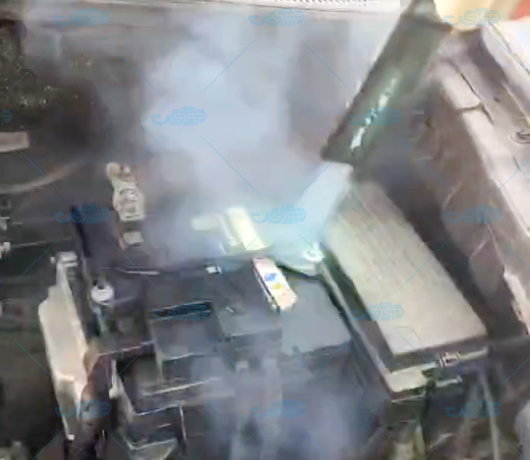

Dry ice cleaning uses solid carbon dioxide and showcases its ultra-low temperature (-78.5 ℃) and sublimation properties. When tiny dry ice particles are sprayed at high speed onto the surface of car molds, the extremely low temperature instantly freezes and embrittlement the attached oil stains, mold release agent residues, metal debris, and other dirt. Subsequently, the strong airflow generated by the sublimation of dry ice forcefully removes these already brittle impurities, without the need for a drop of chemical cleaning agent.

Compared to traditional mold cleaning methods, dry ice cleaning has demonstrated its advantages. In the past, chemical solvents were used for soaking and cleaning, which not only consumed a large amount of chemical agents, but also resulted in high costs for subsequent treatment of wastewater containing harmful components, and was prone to corrosion and damage to molds. Dry ice cleaning has no water or chemical corrosion risk, perfectly protecting the accuracy and surface quality of the mold, greatly extending the service life of the mold.

From the perspective of production efficiency, traditional cleaning methods require long soaking, rinsing, and drying of molds, resulting in long downtime and seriously affecting the production progress of automotive parts. Dry ice cleaning is efficient and fast, which can complete deep cleaning of complex molds in a short period of time, allowing the molds to quickly return to the production line, greatly reducing downtime and waiting time, saving a lot of time and cost for enterprises, and improving overall production capacity.

In addition, dry ice cleaning is flexible and can accurately clean molds according to their different shapes and structures. Whether it is fine interior molds or large body stamping molds, it can achieve ideal cleaning effects, ensuring that automotive molds are always in the best working condition and injecting strong power into the high-quality and sustainable development of automotive manufacturing.

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,