Pain points in automobile manufacturing

The limitations of traditional cleaning methods: In the automotive manufacturing process, component cleaning is a critical step. Traditional cleaning methods, such as solvent cleaning and water washing, have many problems. Solvent cleaning may cause environmental pollution, and the cost of solvents is high, while also posing a safety hazard of flammability and explosiveness. Although water washing is relatively environmentally friendly, it can easily cause rusting of parts, and drying treatment is required after cleaning, which increases the process and time costs.

Complex and difficult to clean components: The structure of automotive components is becoming increasingly complex, with many fine holes, gaps, and hidden parts. For example, the engine cylinder block has criss crossing internal passages, and traditional cleaning methods are difficult to completely remove impurities such as oil stains, iron filings, and burrs. These residual impurities may affect the performance and lifespan of components, and even lead to vehicle malfunctions.

High cleaning efficiency requirements: Automobile manufacturing is a large-scale assembly line production that requires extremely high production efficiency. Traditional cleaning methods often require long cleaning times and complex process flows, which are difficult to meet the fast-paced production pace and can easily cause production bottlenecks, affecting the overall production progress.

Advantages of dry ice cleaning

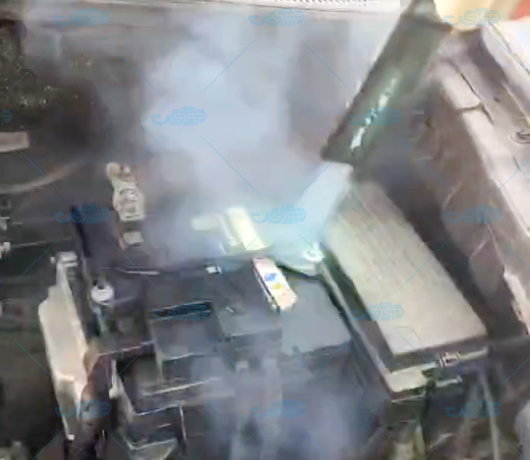

Efficient cleaning: Dry ice cleaning uses compressed air as a power source to accelerate and spray dry ice particles onto the surface of the object being cleaned. When dry ice particles come into contact with the surface of an object, they quickly sublime and expand in volume by about 800 times, generating a strong impact force that can quickly and effectively remove impurities such as oil stains, dirt, rust, etc. For stubborn stains on automotive parts, dry ice cleaning can achieve ideal cleaning results in a short period of time, greatly improving cleaning efficiency and meeting the needs of large-scale production in automotive manufacturing.

Non destructive cleaning: Dry ice cleaning is a non-contact cleaning method, in which dry ice particles do not cause wear or scratches on the surface of parts during the cleaning process. For some precision automotive parts, such as engine cylinder blocks, transmission housings, car wheels, etc., it can protect the accuracy and surface quality of parts while ensuring the cleaning effect, without affecting the performance and assembly accuracy of parts.

Environmental protection and energy conservation: Dry ice used for cleaning is solid carbon dioxide, which sublimates directly into carbon dioxide gas during the cleaning process without any residue and will not cause pollution to the environment. Compared with traditional solvent cleaning and water washing, dry ice cleaning does not require the use of chemical solvents, nor does it consume a large amount of water resources. At the same time, it reduces the steps of sewage treatment and has significant environmental and energy-saving advantages.

Safe and reliable: Dry ice cleaning does not use flammable and explosive chemical solvents, avoiding safety hazards such as fires and explosions. And dry ice can sublime at room temperature, without the risk of burns like washing with hot water, ensuring the safety of operators. In addition, dry ice cleaning equipment is easy to operate, maintain, and runs stably, providing safe and reliable cleaning solutions for automotive manufacturing enterprises.

Dry ice cleaning technology, with its unique advantages, has solved many cleaning problems for the automotive manufacturing industry and is a cleaning technology worthy of widespread promotion and application.www.ntpco2.com

Warm Christmas & New Year Greetings | Professional Dry Ice Equipment Solutions

Warm Christmas Greetings from 【Qingdao Newtep New Energy Technology Co.,