In the realm of dry ice production, the efficiency and conversion rate of dry ice making machines are of utmost importance. Wantong’s intelligent dry ice making machines have emerged as a leading choice, renowned for their high conversion rates. This article delves into the reasons behind the remarkable performance of Wantong’s machines.

Advanced Technology and Precise Control

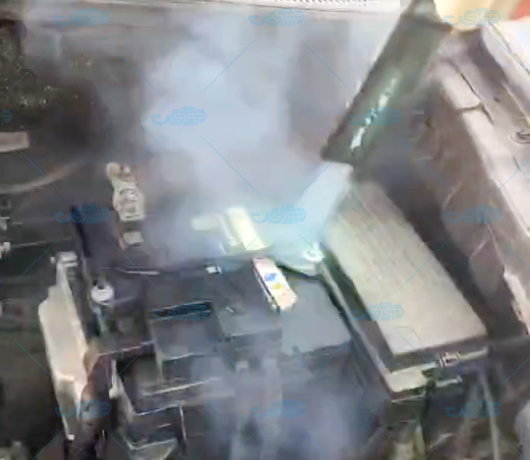

Wantong’s dry ice making machines are equipped with state-of-the-art technology. The process begins with the careful handling of carbon dioxide (CO₂), the raw material for dry ice. The machines use a sophisticated system to pressurize and cool the CO₂ gas. By precisely controlling the pressure and temperature, the conversion from gaseous CO₂ to solid dry ice is optimized. For example, in the pelletizing process, the temperature is maintained at an ideal level around -78.5°C, which is the sublimation point of CO₂. This accurate temperature control ensures that the CO₂ solidifies efficiently into high-quality dry ice pellets, maximizing the conversion rate.

Efficient Cooling Systems

The cooling systems in Wantong’s machines play a crucial role in achieving high conversion. These machines are designed with advanced cooling mechanisms, such as powerful air-cooled or liquid-cooled systems. The cooling process is rapid and effective, quickly removing the heat from the CO₂ gas as it transitions to a solid state. In large-scale production models like the WT-2000, which has a high production capacity of 1000 kg/h, the cooling system is engineered to handle the large volume of CO₂. It cools the gas evenly across the production chamber, ensuring that every part of the CO₂ is converted into dry ice without any wastage, thus contributing to a high conversion rate.

Intelligent Design for Optimal Performance

The intelligent design of Wantong’s dry ice making machines is another key factor. The machines are designed to minimize energy consumption while maximizing output. For instance, they have an intelligent control panel that monitors and adjusts the production process in real-time. If the pressure or temperature deviates slightly from the optimal range, the control system automatically makes the necessary adjustments. This intelligent monitoring and adjustment not only improve the quality of the dry ice but also ensures that the conversion process is as efficient as possible. In addition, the machines are designed with a streamlined internal structure, which reduces resistance and allows for a smooth flow of CO₂ during the conversion process, further enhancing the conversion rate.

High-Quality Components and Durability

To achieve high conversion rates consistently, Wantong uses high-quality components in its dry ice making machines. The pumps, valves, and compressors are all made from durable materials that can withstand the harsh conditions of the dry ice production process. High-quality components operate more efficiently, reducing the likelihood of breakdowns and ensuring a continuous and stable production process. For example, the compressors used in Wantong’s machines are designed to provide a stable and high-pressure environment for the CO₂ gas, which is essential for the efficient conversion to dry ice. The durability of these components also means that the machines can maintain their high conversion rates over a long period, making them a reliable choice for businesses in need of dry ice production.

Customization Options for Specific Needs

Wantong understands that different industries have different requirements for dry ice production. To meet these diverse needs, the company offers customization options for its dry ice making machines. Whether it’s adjusting the size of the dry ice pellets or blocks, or modifying the production capacity, these customization options allow businesses to optimize the conversion process according to their specific needs. For a food processing company that requires smaller dry ice pellets for better cooling of delicate food products, Wantong can customize the machine to produce pellets of the desired size. This customization ensures that the conversion process is tailored to the specific application, resulting in a higher conversion rate for that particular use case.

In conclusion, Wantong’s intelligent dry ice making machines offer a combination of advanced technology, efficient cooling systems, intelligent design, high-quality components, and customization options. These features work together to achieve a high conversion rate, making Wantong’s machines a top choice for industries such as food and beverage, cold chain logistics, and dry ice blasting. With their ability to produce high-quality dry ice efficiently, Wantong’s dry ice making machines are well-positioned to meet the growing demand for dry ice in various sectors.http://www.gbqxsb.com