The prohibitive cost of equipment has prompted the Co2 Dry Ice Cleaning Supply Service, a new cleaning technology for industry . Now it is widely used in kinds of industries such as tire, printing, food, electrical, mold, automobile, and many other industries.

Why dry ice cleaning is better than other cleaning methods ?

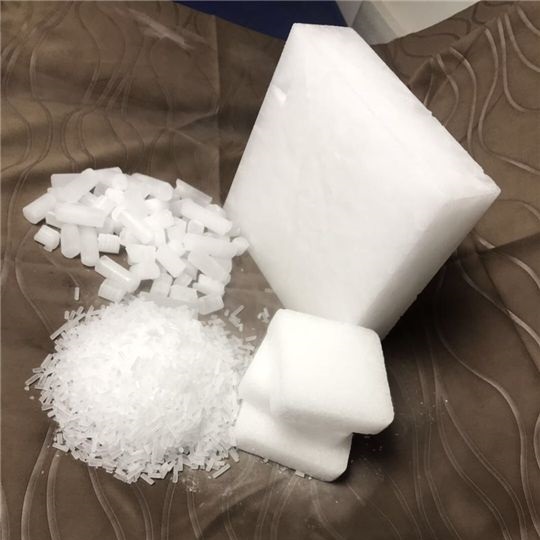

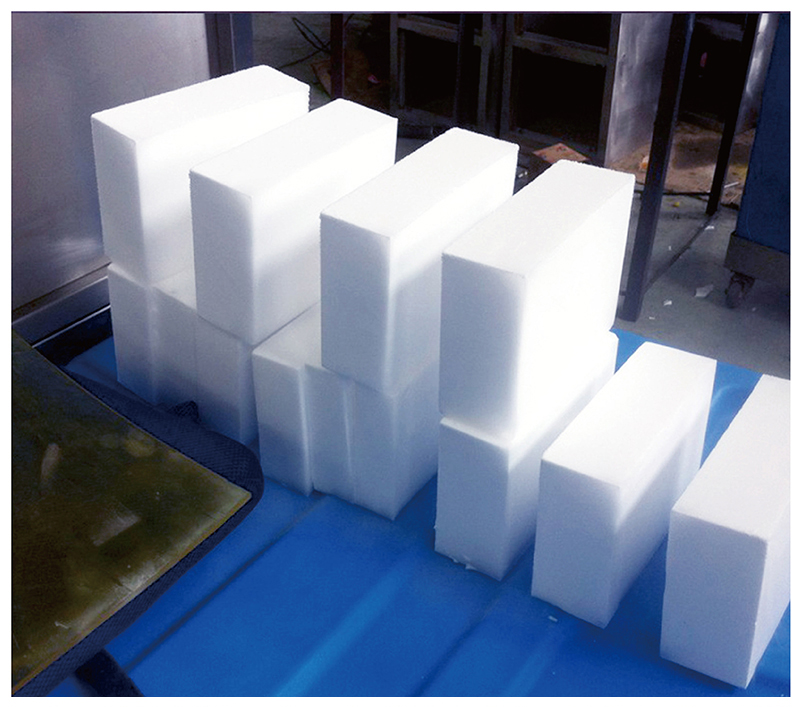

Dry ice blast cleaning is a process in which particles of solid carbon dioxide are propelled at a high velocity to impact and clean a surface.

Dry ice blasting is particularly powerful for cleaning machinery and creating hardware. Unlike different media effects, dry ice cleaning have no additional waste or auxiliary pollution. When dry ice particles come into contact with surfaces that need cleaning, they change from strong particles to CO2 gases in a process called sublimation, without discarding any sediment. It is non-abrasive, non-conductive and non-flammable.

The advantages of this method are summarized as follows:

Reduced Down time – enables most things to be cleaned in place.

Is a non-rough, nonflammable and non conductive cleaning method.

Is earth well disposed and contains no optional contaminants, for example, solvents or coarseness media.

Cleans even Hard to Reach nooks and crannies.

Can be utilized to evacuate generation deposits, discharge specialists, contaminants, paints, oils and bio films.

Can be utilized without harming dynamic electrical or mechanical parts or making fire hazards.

Can be as gentle as dusting smoke damage from books or as aggressive as removing weld slag from tooling.

Increases Machine and molds life.

Case : Dry Ice Cleaning Heat Voltage Coils

As the power output of factory equipment, the high voltage motor will affect the production and operation of the factory once there is a problem. In order to ensure the normal operation of the high-voltage motor, it is necessary to carry out regular maintenance every once in a while, so that some minor faults can be found early and eliminated to prevent bigger faults.

In view of the complexity and number of components of the high-voltage motor, it will be a considerable project to remove and clean one by one, which will also consume time and energy. So the factory chose our Dry ice blaster machine to achieve to achieve the purpose of cleaning . During cleaning process, for different parts only need to replace the appropriate cleaning nozzle to complete the operation, efficient and fast.

Let us have a look of photo that before cleaning and after cleaing :

Detailed display please view here : https://youtu.be/uew04D8xsKs

If you also have any cleaning problems , and want to choose dry ice blasting , welcome to contact us , a good solution will be made for you .