In 2019, the concentration of carbon dioxide(CO2) in the world’s atmosphere exceeded 410ppm, while the average before industrialization (Year of 1750) was only 278ppm. Carbon dioxide emissions from factories accounted for 10-30% of the overall emissions. The increasing concentration of CO2 in the air caused the global temperature rise and the frequent occurrence of extreme climate disasters.

2016 Paris agreement the long-term goal is to the global average temperature rise during the period of the previous industrialization control within 2 degrees Celsius, and to limit temperature rise to 1.5 degrees Celsius. According to the international energy agency (IEA), in order to achieve this goal, the need to increase the recovery of the amount of carbon dioxide by 2050 to the present nearly 200 times.

How to effectively reduce carbon dioxide emissions, realize the recovery and recycling of carbon dioxide has become a new topic facing the world.

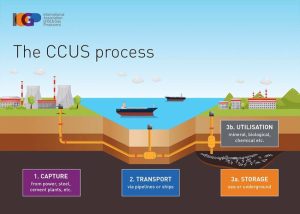

In China, many enterprises are also constantly seeking new technologies and opportunities to explore the potential and benefits of carbon dioxide recovery. In 2019, There were 18 carbon capture projects in operation in China, which captured about 1.7 million tons of CO2.

For examples . A chemical plant uses the carbon dioxide emissions from the existing production process to produce food grade liquid CO2 and solid type – a dry ice production line ,via psa and purification processes. Through the implementation of the new project, the plant has the capacity to recover 150,000 tons of CO2 exhaust gas annually, realizing 65 million yuan annual output value, while saving 0.75 million tons of standard coal.

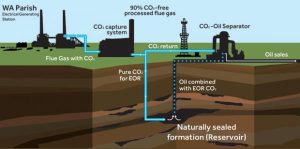

Another refining and chemical company uses carbon capture technology to capture high-carbon, high-heat waste gas released from the plant; and then uses stage purification technology to desorption and compression to form liquid CO2. LCO2 is then injected into production Wells to drive oil and gas production, increasing production while reducing CO2 emissions.

Therefore, although carbon dioxide is one of the scourge of environmental pollution, it is also a potential organic carbon resource. This requires people from all walks of life to constantly innovate and explore more effective environmental protection energy technologies, develop the recovery and comprehensive utilization of CO2 waste gas, and reduce carbon emissions. In the realization of green and sustainable development of the enterprise at the same time to help the global carbon peak, carbon neutral vision goal.